The Croma PLUS series of coordinate measuring machines are precision instruments specially designed for complex surface detection, which combine accuracy and speed, setting new standards for accuracy and efficiency. Complete various complex measurement tasks with high precision and efficiency, meeting the diversified testing needs of various industries.

Efficiency wins over PC-DMIS scanning module, making measurement easier

The PC-DMIS scanning module, combined with the Hexagon X1 two in one sensor (scanning and triggering), can perform surface scanning on the workpiece, completing 100 point acquisition in seconds, and improving efficiency several times.

· DCC Scanning module

· The length of the measuring needle can reach up to 225mm, making it convenient for deep hole measurement;

· Equipped with a small scanning probe with a diameter of only 30mm, it has anti-collision protection function;

· Measurement accuracy 2.0 μ Starting from m;

PLUS precision is paramount, not just precision+

CROMA PLUS provides a high-performance control system for the stable and reliable three-axis mechanical structure of Serein. It is equipped with a widely recognized Hexagon scanning probe as standard, which has high measurement accuracy and greatly improves the measurement efficiency of the equipment.

Crafty design accurately reflects every detail

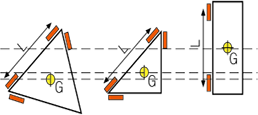

The all-new Croma inherits the classic design of an all aluminum frame, 60 ° precision triangular crossbeam, and integral dovetail X-way guide rail. The Croma Plus exudes inherent professionalism, achieving a seamless and smooth pleasure. The group's global supplier platform and standard process flow jointly ensure every detail.

|  |

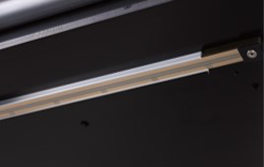

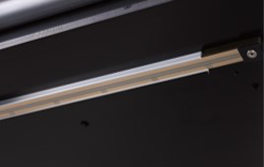

1. Installation method of grating The thermal expansion coefficient of the grating has obtained PTB certification. During assembly, one end is fixed and the other end can freely expand and contract with temperature changes.

| 2. Phosgene dynamic balance technology Advanced pneumatic balance technology, using a flexible suspension system and patented damping balance mechanism, improves the dynamic characteristics of the machine and strengthens the safety guarantee of the Z-axis. |

|  |

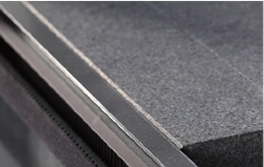

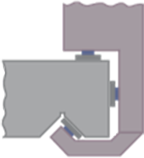

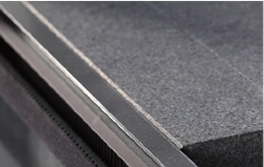

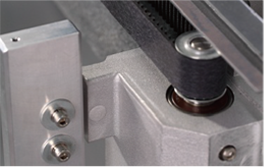

3. Integral dovetail guide rail The integrated dovetail shaped guide rail improves the operating accuracy of the entire machine. | 4. Movable bridge structure The advanced movable bridge structure provides a more open measurement space. |

|  |

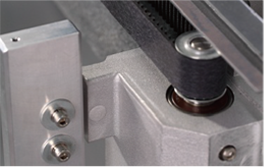

5. High precision air flotation system Each shaft adopts preloaded air bearings to eliminate the impact of friction and running wear on the machine, and is not sensitive to on-site dust. | 6. Standard process flow The thick and stable overall granite workbench reduces the impact of vibration, and the flatness of the workbench meets the DIN876 standard. |

|  |

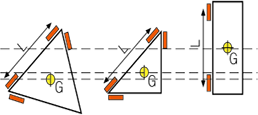

7. Remote placement of drive motor Remote placement of motors reduces movement quality, improves speed, and avoids the impact of motor heating on machine performance. | 8. High precision triangular beam technology The TRICISIONTM beam design reduces the center of gravity and is lighter than other forms of beams with equal width bearing spans. |

Application Cases

Two well-known measurement software options in the industry, tailored to customer needs

PC DMIS has long led the development of software application technology in the metrology industry with its professional measurement technology, continuous technological innovation, simple operation functions, and extensive compatibility. More than 600000 people worldwide use PC-DMIS, which has become a commonly used measurement software in the industry.

Rational DMIS software has been highly praised by CMM industry experts for its intuitive, powerful, and efficient features, and has also won the trust of users in industries such as automobiles, airplanes, engines, ships, and molds. In 2018, Hexconn acquired Rational DMIS software to provide more software options for measurement, especially its powerful customization functions, providing enterprises with services that are more tailored to customer needs.